3D 프린팅 빨라졌다..."2시간 만에 3D 제품 제작"

기사입력 2024.05.13 14:57

▲폼랩코리아 이경준 지사장

전작대비 속도·신뢰성·경제성↑, 올해 30% 성장 목표

의료·제조·드론 등 활용 확대, 다품종 소량 시장 타겟

전작대비 속도·신뢰성·경제성↑, 올해 30% 성장 목표

의료·제조·드론 등 활용 확대, 다품종 소량 시장 타겟

의료, 제조, 로보틱스 등 다양한 산업군에서 3D 프린팅 기술이 확산되고 있는 가운데, 폼랩이 평균 부품 제작을 2시간 내외로 줄이고, 신뢰성과 경제성을 확보한 폼 4를 공개했다.

3D 프린팅 재료 및 하드웨어 분야 기업 '폼랩(Formlabs)'이 13일 잠실에서 기자간담회를 개최해 4세대 데스크톱 3D 프린터 신제품 '폼 4(Form 4)'을 소개 및 시연했다.

폼랩코리아 이경준 지사장은 "향상된 성능, 신뢰성, 경제성을 확보한 폼랩의 새로운 3D 프린터 폼 4는 출시 후 2주 동안 기존 폼 3+보다 판매 속도가 3-4배 정도 빠르다"며, "올해 전년 대비 약 30%의 성장률을 목표하고 있다"고 포부를 드러냈다.

또한 "3D 프린팅 업계는 장비, 노동력, 재료 등 파트당 단가를 줄이는 것이 가장 중요하다. 1천개 정도의 제품을 제조하는 다품종 소량 생산 고객을 두고 있는 폼랩은 기술력 확보, 자동화 구현, 재료 다량 구매 시 비용 절감 등으로 가격 경쟁력을 확보했다"고 말했다.

특히 중국에서 저렴한 단가의 제품이 납품되고 있는 가운데, 한국은 3D 프린터 시장 경쟁력을 확보하기 까다로운 시장으로 손꼽힌다. 이 지사장은 "국내에서는 최종 부품으로 3D 프린터를 사용하는 경우는 아직 많지 않지만, 단가가 중국의 영향을 받을 수밖에 없다"고 말했다.

이에 대해 폼랩은 고품질의 3D 프린팅 기술을 무기로 삼는다. 이 지사장은 "시간, 보안과 신뢰성을 중요하게 고려하는 고객들은 국내 생산을 충분히 염두하고 있다"고 말했다.

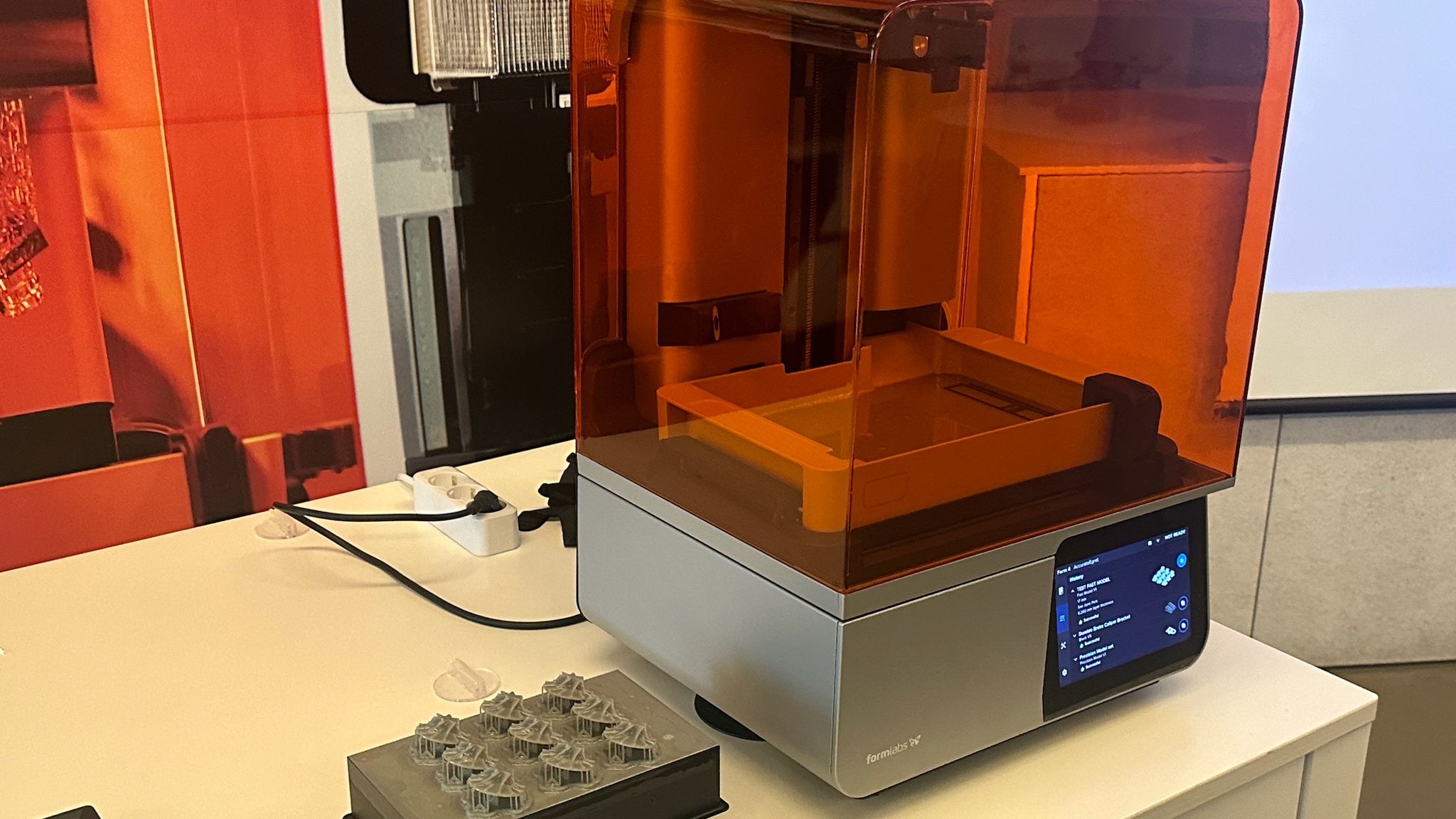

이번 발표한 폼랩의 신제품 '폼 4'는 기존 대비 성능이 대폭 향상됐다. 소재에 따라 기존 '폼 3+(Form 3+)' 제품보다 최소 2배 최대 5배 빠른 속도로 제품을 인쇄해 시제품 반복 제작 또는 mSLA(광조형) 기술을 사용한 일괄 생산이 가능하다. 폼 4의 시간당 수직 프린트 속도는 최대 100mm로, 이에 따라 대부분 제품을 2시간 내, 소형 제품은 몇 분 내로 제작할 수 있다.

예컨대 11개의 치과 관련 제품 제작 시 기존에는 40-50분만에 출력됐던 반면, 폼 4는 9분만에 출력해 최대 3-4배의 시간을 절약할 수 있게 됐다. 반복 작업 시에도 장비 내 카메라를 통해 2시간마다 출력물을 모니터링할 수 있어 조기에 불량을 확인 및 제작 시간을 단축할 수 있게 됐다.

다비드 라카토스(David Lakatos) CPO는 "사출 성형(Injection molding)을 3D 프린팅으로 전부 대체할 수는 없지만, 소량 또는 고객 맞춤형인 경우 3D 프린터가 사출 성형보다 약 20분 빠른 속도, 3분의 1 가격 수준 등 경쟁력이 있다는 점을 확인했다"며, "특히 3D 프린터는 몰딩의 디자인을 디자인을 계속 변경하거나 제조상에서 수정이 필요할 경우 이를 적용하기 더 쉽다는 이점이 있다"고 말했다.

▲신제품 3D 프린터 폼 4와 시연 제품

폼랩은 전력 소모와 발열 문제도 잡았다. 다비드 라카토스 CPO는 "따로 전선을 뽑아 공급할 필요 없이 바료 연결할 수 있는 폼 4는 기존 폼 3+ 대비 전력 소모는 유사하며, 다른 사출 장비보다는 우수하다"고 말했다. 또한 3D 프린터에는 예열로 시작해 프린팅을 하는 동안 탑재된 팬으로 발열 시 쿨링 효과를 줄 수 있게 됐다.

신뢰성을 확보하고 경제성도 갖추었다. 오래 지속되는 재료 탱크(75,000 레이어 이상)와 광 처리 장치(1백만 레이어 이상)를 탑재했고, 프린트 볼륨은 30%가 더 커졌다. 처리량이 3.5배 높아져 폼 3+에 비해 부품당 비용을 최대 40% 절감할 수 있다는 설명이다. 폼 4의 장비는 한 대당 480만원부터 최대 780만원 정도로 책정됐다.

또한 폼랩은 전문 자회사를 두고 재료 개발에 힘을 쓰고 있다. 재료 라이브러리에 폼 4 에코시스템을 활용해 폼 3보다 2-5배 더 빠르게 프린트할 수 있도록 새로운 레진이 추가됐다. 재료 라이브러리에서는 17개 이상 다른 성능 재료를 사용할 수 있도록 검증이 완료됐으며, 새로운 재료가 정기적으로 추가될 예정이다.

이에 따라 기존 국내 범용 재료 비용이 23만원 정도에 책정됐다면, 새로운 장비에서는 동일한 용량으로 13만원 정도에 불과해 가격이 기존 대비 40% 낮아졌다. 이에 더해 폼랩은 3D 프린팅을 위한 무료 소프트웨어 '프리폼(PreForm)'과 3D 프린터 관리 도구 '플릿 컨트롤(Fleet Control)'을 제공한다.

다비드 라카토스 CPO는 "13만 대 이상의 프린터와 3억 개 이상의 부품을 제작하여 얻은 노하우로 출시한 SLA 프린터 폼 4를 한국에서 선보일 수 있어 의미가 깊다"고 덧붙였다.

한편 2011년도 설립된 폼랩은 SLA 및 SLS 3D 프린터, 후처리 솔루션, 오토 제조 솔루션 등을 공급하고 있다. 폼랩의 장비는 인텔, 지멘스, 구글, LG전자 등 대기업을 비롯해 국내 공공기관과 대학교, 금융기관, 드론 제조업체, 자동차 부품 업체 등에서 광범위하게 사용되고 있다.

많이 본 뉴스

[열린보도원칙] 당 매체는 독자와 취재원 등 뉴스이용자의 권리 보장을 위해 반론이나 정정보도, 추후보도를 요청할 수 있는 창구를 열어두고 있음을 알려드립니다.

고충처리인 장은성 070-4699-5321 , news@e4ds.com