14일 코엑스 컨퍼런스룸에서 개최된 산업데이터 퓨처콘 2024에서 산업 데이터 국제표준화위원회 컨퍼런스와 첨단제조 표준화 포럼이 동시 개최됐다. 포럼에서는 글로벌 데이터 표준화 동향 및 연구 방안에 대한 논의와 토론이 진행됐다.

ISO 8000, 데이터 품질 국제 표준 제정

표준화 시맨틱 상호 운용성, 고품질 제조 실현

정보화 시대 기업의 폭증하는 데이터가 중요한 자산으로 자리매김하는 가운데, 산재된 데이터를 수집 및 분석해 정보화 하는 과정에서 데이터 품질의 확보는 필수적이다. 업계에서는 데이터의 의미 손실 없이 상호 교환을 가능케 하는 데이터 표준화 작업이 강조되고 있다.

14일 코엑스 컨퍼런스룸에서 개최된 산업데이터 퓨처콘 2024에서 산업 데이터 국제표준화위원회 컨퍼런스와 첨단제조 표준화 포럼이 동시 개최됐다. 포럼에서는 글로벌 데이터 표준화 동향 및 연구 방안에 대한 논의와 토론이 진행됐다.

기조연설에서 ACS 차석근 부사장은 “제조 현장에서 현장의 데이터가 신뢰성이 없으면 결과도 엉터리로 이어진다. 첨단 제조 표준화를 통해 제조 현장 혁신을 달성하고, 글로벌 주도권을 확보해야 한다”고 주장했다.

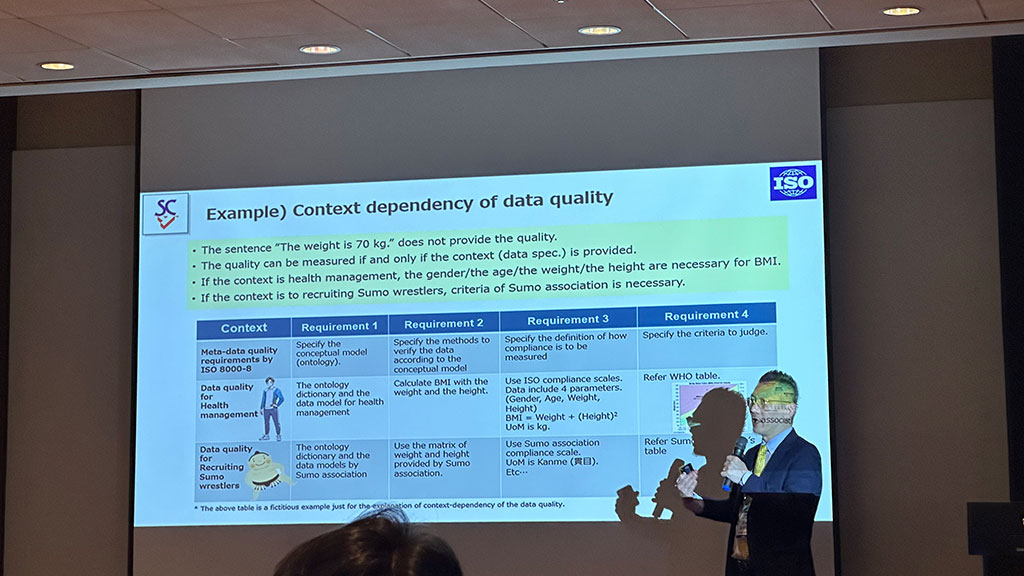

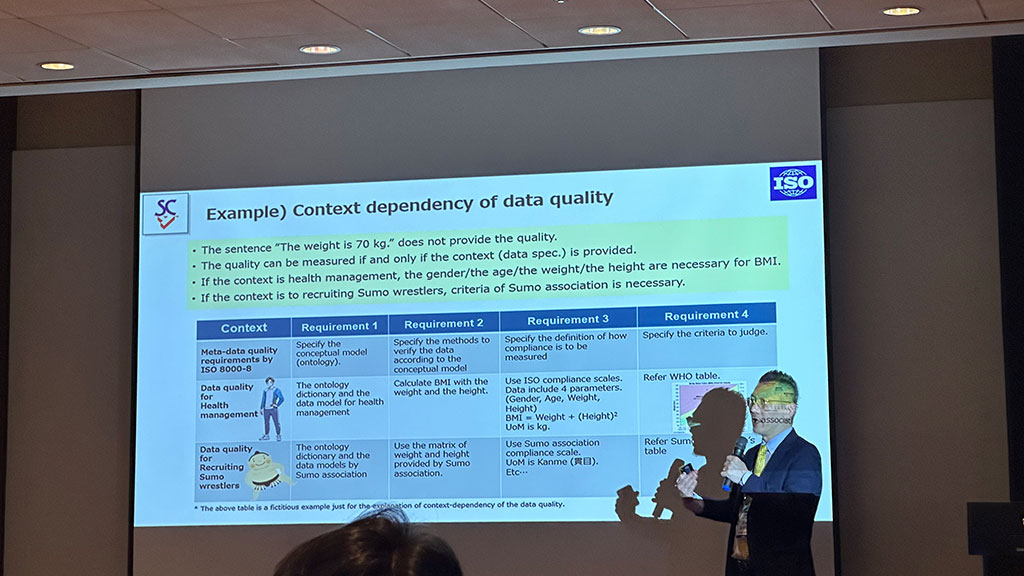

이어진 세션 발표에서 전문가들은 스마트팩토리에서 데이터 품질 확보의 시작은 컨센서스의 합의를 통한 용어 사전적 정의에서 시작한다고 의견을 모았다. 데이터의 품질을 판단할 수 있는 적합한 기준을 설정하고, 검증해야 한다는 설명이다.

예컨대 ‘로봇’에 대한 개념에서도 데이터 수준의 차이가 존재할 수 있다. 우리나라와 주요 첨단 기술을 주도하는 국가에서 떠오르는 ‘로봇’의 개념과 달리 디지털화 되지 못한 국가의 시민들은 ‘로봇’을 신호등이라 생각할 수 있다. 그러나 ‘로봇’이라는 단어를 교환할 때 발생할 수 있는 사전적 오류에 대해 의미 정의부터 규정한다면 데이터 교환 시 동일한 개념을 떠올리게끔 할 수 있다는 것이다.

MRO Insyte 피터 에일스(Peter Eales)는 “최근 공장들이 데이터 품질과 상호 운용성의 문제를 겪고 있는 가운데, 데이터 관리에는 적당한 체계가 필요하다”며, “IOS 8000 인증은 다양한 역할로 데이터를 나눠 다루고, 객관적으로 검증 및 증거 기반의 신뢰성을 제공할 수 있다”고 말했다.

국제표준기구 ‘ISO(International Standard Organization)’에서는 각국 간의 합의를 통해 국제적으로 통용되는 표준을 정한다. 소비자에게 알려진 ‘ISO 9000’은 제품 품질과 관련된 내용을 다루고 있다.

‘ISO 8000’은 ISO 9000의 자매와 같은 표준으로, 2000년대 초반부터 센서 데이터 등 데이터 품질에 대한 표준을 제정하고 있다. ISO 8000은 미국, 영국, 독일 등을 중심으로 확산돼 국내에서도 민간 및 공공 분야에서 도입되고 있다.

이어진 발표에서 미쯔비시중공업 요시아키 소노다(Yoshiaki Sonoda)는 물리적 또는 가상화 환경에서 시맨틱 상호 운용성 확보를 강조했다. ‘시맨틱 상호 운용성’은 데이터의 의미를 이해 및 해석을 바탕으로 서로 다른 시스템 간 원활한 정보 공유를 가능케 하는 기술을 의미한다.

요시아키 소노다는 “표준화된 시맨틱 상호 운용성은 고품질의 제조화를 실현한다”며, “모든 비즈니스 데이터는 객체(Attributer)에 ID를 붙여 식별하는 방식의 ‘의미론적 기술 사전(Ontology Dictionaries)’에 의해 재구성돼야 한다”고 말했다.

또한 “이러한 스마트 데이터 전략을 통해 데이터의 의미를 정확하게 이해하고, 서로 연결해 활용할 수 있도록 지원할 수 있다”고 덧붙였다.