Editor’s Note: e4ds News aims to help readers to choose products by highlighting the functionalities and features of various MCUs as well as the technologies and trends focused by leading MCU companies.

Cypress, renowned for its SRAM and PSoC processor lineups, was merged with Spansion, which is strong in memories and automotive MCUs, in early 2015. We met Hyung-Joon Kim and Hwan-Kook Cho, managers of Cypress Semiconductor, to glimpse into the future of the company’s MCUs.

■ What are the main products of your MCU lines?

Hyung-Joon Kim (Kim hereafter): Our MCUs mainly focus on automotive applications. First, we would like to introduce our programmable PSoC. The feature differentiating it from existing MCUs is that it allows users to include functions of their choice into it. While MCUs from competitors have fixed peripherals, our PSoC allows users to mount any functionality on it using our tool, as if playing with lego blocks.

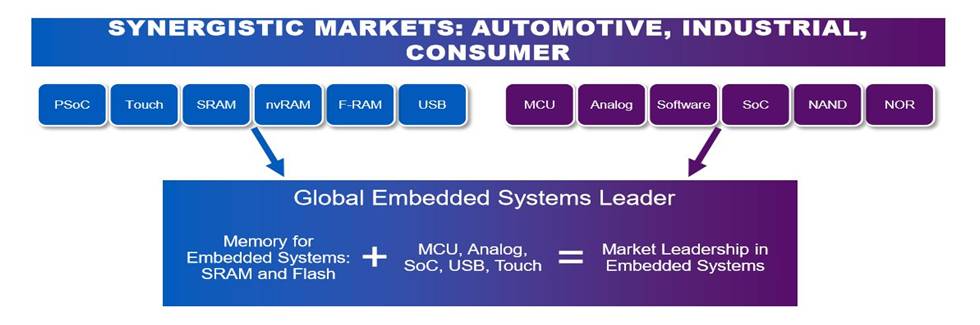

▲ Synergy effect generated from merging of Cypress and Spansion.

“Cypress focuses on automotive clusters and bodies with its Auto MCU products and on Automotive True Touch, Capsense and BLE with its PSoC based products.” _

Hyung-Joon Kim / Cypress Korea

■ Is cluster the main focus of automotive MCUs?

Hwan-Kook Cho (Cho hereafter): Yes, it is. Automotive field is not limited to an application. Its development can be expanded to include clusters, bodies, electric vehicles, power trains, motors, etc. In particular, we refer to our automotive MCUs as Traveo. Automotive MCUs of Cypress are based on Cortex R5 and provide convenient functionalities including human interface. For example, you can develop one-chip solutions with them as they have cluster systems integrated into them. We plan to keep expanding our automotive market share on the basis of ARM cores.

■ Do you plan to release all your new products based on ARM cores? If so, what would be the reason?

Cho: There is this general trend of moving toward common core. However, every semiconductor company investing in individual core will result in overlapping investments. On the contrary, investment done within the boundary of ARM-based core will lead to cost reduction effect. Besides, using proprietary core increases reliance on particular core, making it hard for car OEMs to control prices regardless of the product’s performance. We introduced ARM-based products to deal with just this kind of problem. And ARM core is open to any body, allowing us to expand a resource into next project or even to different one.

“Combining Traveo series and True Touch Auto PSoC products, development of product lineups meeting the requirement of currently-popular high-resolution, touch-screen display will be continued.”

Hwan-Kook Cho_Cypress Korea

■ What is the main characteristics of ‘Traveo,’ the automotive MCU?

Cho: Cypress had a high-performance graphic engine built into Traveo to implement one-chip solution. So there is no need to have a separate graphic chip called graphic display controller for external display. In addition, this solution does not require external memory as it already has one-chip memory, memory control and VRAM built into it.

▶ Traveo chip from Cypress

■ Infotainment is one of those fields demanding high volume of data. Wouldn’t it require external memories?

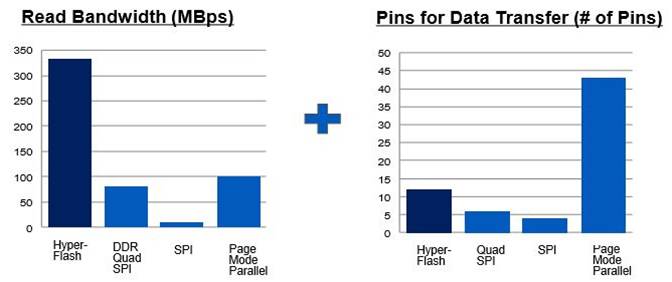

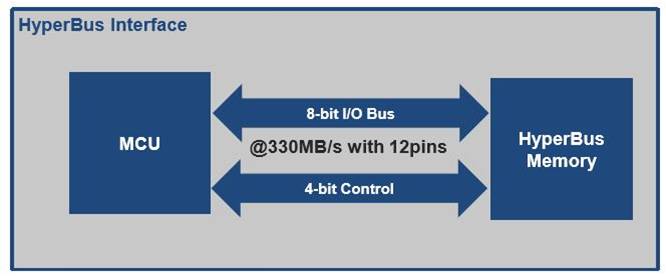

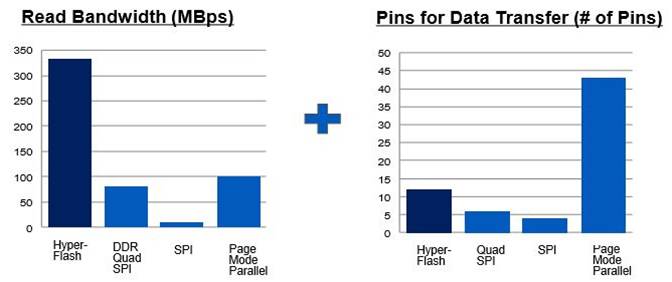

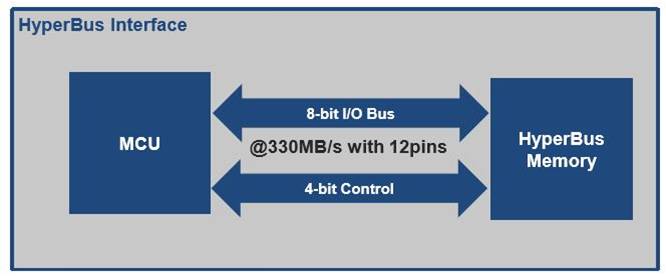

Cho: Yes, you’re right. That’s why Cypress provides HyperBus solution in case you need external memories. The solution enables access to external flashes and RAMs with low pin count and wide bandwidth. Increased communication speed with low pin count is the solution’s strong point.

▲HyperBus featuring low pin count and wide bandwidth

▲HyperBus interface

■ In terms of memories or MCU products, what kind of synergy effect is Cypress achieving through merging with Spansion?

Cho: As memory takes up the most space in wafer, reducing it is core technology in terms of cost reduction. The area memory takes up in MCU is larger than generally expected. Also possessing memory technology, Cypress can reduce the die size. Depending on core size, the area is reduced to two third, improving yield per wafer. This translates into higher competitiveness.

■ What is the roadmap for Cypress MCUs?

Cho: “Combining Traveo series and True Touch Auto PSoC products, development of product lineups meeting the requirement of currently-popular high-resolution, touch-screen display will be continued.”