의료기기는 누설 전류 500μA 이하, 내전압 1500~4000V, 연면거리 3.2mm(보강 절연 6.4mm) 이상을 준수해야 한다. 절연 결함은 환자 화상 및 감전 사고를 유발할 수 있으며, 절연 모니터링 장치는 이를 예방하는 데 필수적이다.

의료기기는 환자와 의료진의 생명과 직결되는 장비로, 설계 단계에서부터 다양한 안전 기준을 철저히 준수해야 한다. 특히 전기적으로 작동하는 의료기기의 경우, 감전 및 화재와 같은 전기적 위험을 방지하기 위한 절연(Insulation)이 필수적이다. 절연이 부실하면 심각한 사고로 이어질 수 있으며, 이는 막대한 비용 손실과 신뢰도 하락으로 연결된다. 본 글에서는 의료기기에서 절연의 필요성과 실제 사례를 통해 절연 설계가 개발시 얼마나 중요한지에 대해 다룬 기사이다.

절연의 정의와 필요성

의료기기의 절연은 감전 및 장비 고장으로부터 사용자를 보호하는 기술이다. 심장 모니터, MRI, 전기 수술기와 같은 의료기기는 환자의 피부에 직접 접촉하거나 체내에 삽입되므로 절연 설계가 필수적이다. 이를 위해 IEC(International Electrotechnical Commission) 60601-1 표준은 의료기기의 안전성을 보장하기 위해 절연 설계에서 두 가지 보호 수단(MOP, Means of Protection)을 요구한다. 첫 번째는 기본 절연(Basic Insulation), 두 번째는 보강 절연(Reinforced Insulation)으로, 이를 통해 단일 절연 파손이 발생하더라도 기기 사용이 안전하게 유지된다.

절연 기술의 주요 요소

의료기기의 절연 성능은 다양한 요소를 통해 평가되며, 주요 항목은 다음과 같다.

- 누설 전류(Leakage Current) :

의료기기는 누설 전류는 의료기기에서 외부로 새어나가는 미세한 전류로, 정상적인 상태에서도 일정 부분 발생할 수 있다. IEC 60601-1에서는 환자가 접촉하는 부분의 누설 전류가 500μA(마이크로암페어)를 초과하지 않도록 규정하고 있으며, 이는 환자의 감전 및 부작용을 방지하기 위함이다. 특히 심장이나 신경과 같이 민감한 부위에서 사용되는 기기의 경우 누설 전류 기준은 더욱 엄격하게 적용된다.

이 기준은 환자와 의료진의 안전을 보장하는 최소한의 요건으로, 기기의 전원부 설계 및 절연 성능에서 핵심적인 역할을 한다. 따라서 정기적인 누설 전류 검사와 절연 상태 점검은 의료기기의 안전성을 유지하는 데 필수적이다. 절연 결함은 환자 화상 및 감전 사고를 유발할 수 있으며, 절연 모니터링 장치는 이를 예방하는 데 필수적이다.

- 내전압(Withstand Voltage):

내전압은 의료기기의 절연 성능을 검증하는 핵심 지표로, 기기가 고전압 환경에서도 정상적으로 작동하며 감전, 누설 전류 및 화재와 같은 위험을 방지할 수 있는지를 평가하는 과정이다. 이 시험은 의료기기의 전원부 및 절연 설계의 품질을 판단하는 중요한 절차로, 일반적으로 1500V에서 4000V 사이의 전압이 인가된다. 특히 환자와 직접 접촉하는 의료기기의 경우 더 높은 내전압 기준이 적용되며, 기기 유형 및 사용 환경에 따라 요구 조건이 달라진다.

IEC 60601-1 표준은 의료기기의 내전압 요구 사항을 명시하고 있으며, 설계 및 제조 단계에서부터 이 기준을 충족하는 것이 필수이다. 내전압 시험을 통해 절연 결함이 조기에 발견될 수 있으며, 이는 의료기기 안전성을 유지하고 제품 신뢰도를 높이는 데 중요한 역할을 한다.

- 연면거리(Creepage Distance)와 간격(Clearance):

연면거리는 전류가 흐르는 부품 간의 절연 표면을 따라 측정된 거리로, 오염, 습기 및 먼지와 같은 환경적 요인으로 인해 전기적 트래킹(tracking) 현상이 발생하는 것을 방지하는 데 중요한 역할을 한다. 간격(Clearance)은 공기를 통해 측정된 두 도전성 부품 간의 최소 거리로, 기기의 내부에서 전기 아크(arc) 및 절연 파괴를 방지하는 데 필수적이다.

IEC 60950-1 및 IEC 60601-1 표준에서는 기본 절연의 경우 최소 3.2mm, 이중 및 보강 절연의 경우 6.4mm 이상의 연면거리를 요구한다. 또한 의료기기가 사용되는 환경의 오염도(Pollution Degree)에 따라 더 높은 연면거리와 간격이 필요할 수 있다. 고습도 및 고오염 환경에서 작동하는 장비는 더 긴 연면거리를 요구받으며, 이를 충족하지 못할 경우 전기적 안전성에 심각한 문제가 발생할 수 있다. 설계 단계에서 이러한 요소를 고려해 충분한 연면거리와 간격을 확보하는 것은 기기 안전성과 신뢰성을 보장하는 데 필수적이다.

의료기기 절연의 실제 사례

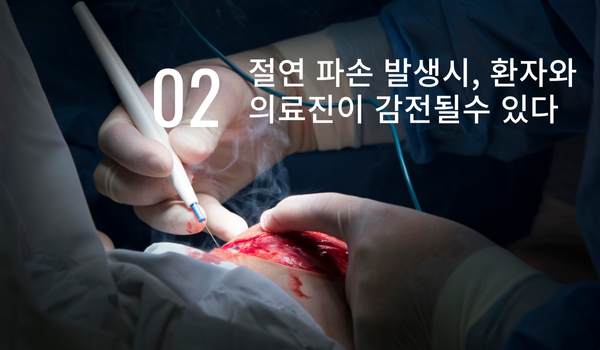

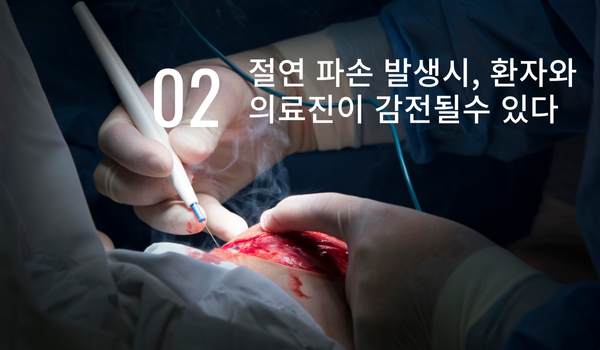

(1) 전기 수술 장비의 절연 파손 사례

전기 수술 장비는 고주파 전류를 사용하여 조직을 절단하거나 지혈하는 데 사용된다. 절연 파손이 발생하면 전류가 잘못 흐르게 되어 환자와 의료진이 감전될 위험이 있다. 실제 사례로, 절연 손상으로 인해 전기 수술 중 환자가 2도 화상을 입은 사례가 보고되었다. 이러한 사고는 적절한 절연 설계와 정기적인 장비 점검을 통해 예방할 수 있다.

(2) 절연 모니터링 장치(IMD)의 활용 사례

절연 모니터링 장치(Insulation Monitoring Device, IMD)는 의료 전기 시스템에서 절연 저항을 지속적으로 감시하는 장치다. 중환자실과 수술실에서는 다양한 의료기기가 사용되므로 절연 결함이 발생할 가능성이 높다. IMD는 절연 저항이 설정 값 이하로 떨어질 경우 경고를 보내 조치를 취할 수 있도록 한다. 이로 인해 감전 사고가 사전에 방지된다.

의료기기의 절연은 환자와 의료진의 안전을 보장하는 중요한 기술이다. 누설 전류, 내전압, 연면거리 등 다양한 요소를 통해 절연 상태를 점검해야 하며, IEC 60601-1 등 국제 표준을 준수하는 것이 필수적이다. 또한, 절연 모니터링 시스템을 도입하고 정기적으로 장비를 유지보수하는 것이 중요하다.

의료기기 제조사들은 절연 기술을 지속적으로 발전시키고 사용자 교육을 강화하여 전기적 위험으로부터 보호 수준을 높여야 한다.