최근 자동차 및 산업기기에서 고전압화가 가속화되며 차량용 전동 컴프레서나 HV 히터, 산업기기 인버터에 탑재되는 파워 디바이스에도 고전압 대응이 요구되고 있다. 또한 저전력화, 냉각 기구의 간소화, 소형화의 관점에서 파워 디바이스의 고효율화에 대한 요구도 높아지고, 자동차 전장 부품에서는 자동차기기 신뢰성 규격에 대한 준거 요구가 증가하고 있다. 특히 인버터·히터 회로에서 파워 디바이스에 단락 시 전류 차단이 요구되는 등 높은 단락 내량 특성 구비가 필요해지고 있다.

차량용 전동 컴프레서·산업기기 인버터 고효율화 기여

최근 자동차 및 산업기기에서 고전압화가 가속화되며 차량용 전동 컴프레서나 HV 히터, 산업기기 인버터에 탑재되는 파워 디바이스에도 고전압 대응이 요구되고 있다. 또한 저전력화, 냉각 기구의 간소화, 소형화의 관점에서 파워 디바이스의 고효율화에 대한 요구도 높아지고, 자동차 전장 부품에서는 자동차기기 신뢰성 규격에 대한 준거 요구가 증가하고 있다. 특히 인버터·히터 회로에서 파워 디바이스에 단락 시 전류 차단이 요구되는 등 높은 단락 내량 특성 구비가 필요해지고 있다.

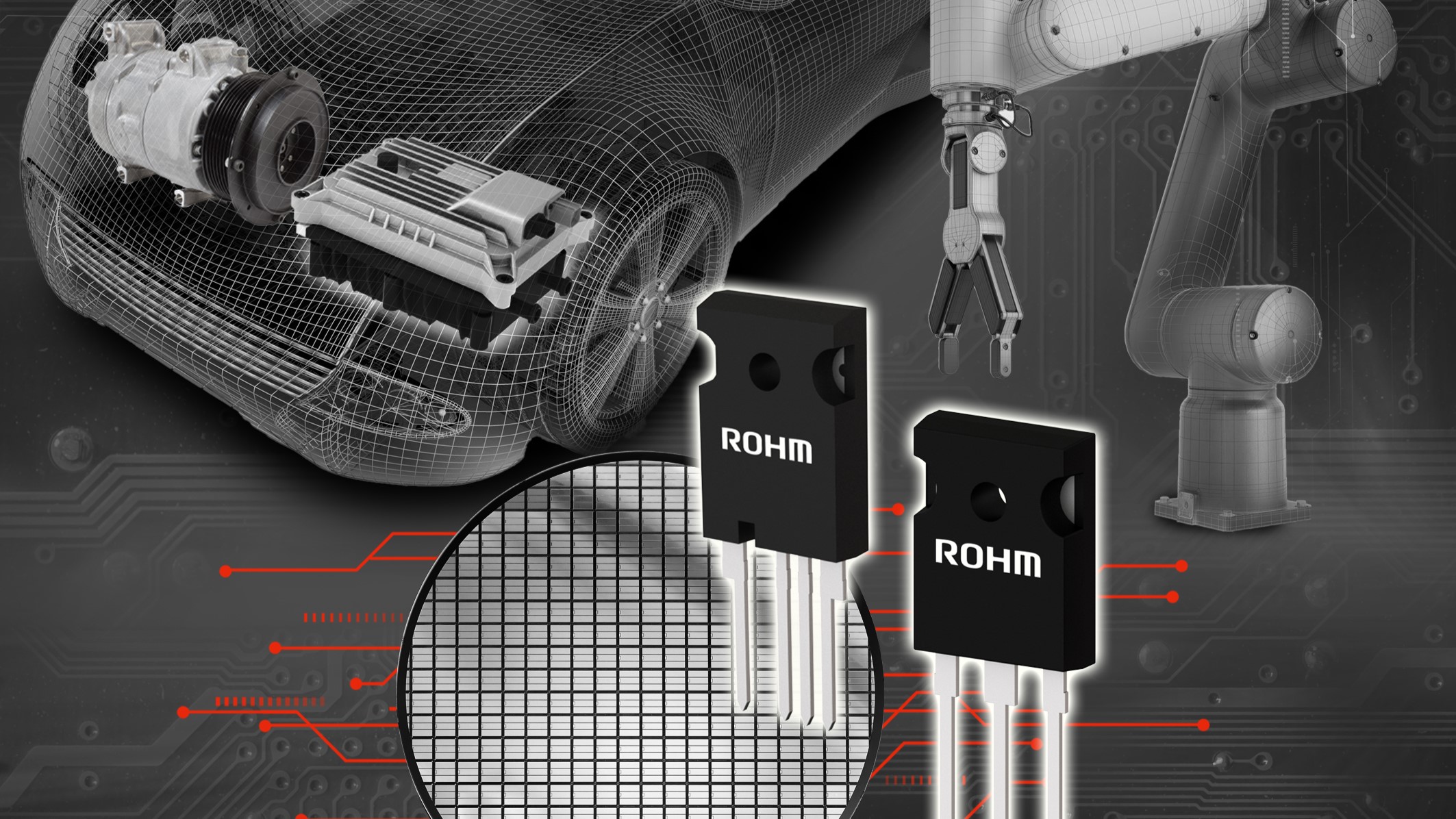

로옴(ROHM) 주식회사가 차량용 전동 컴프레서 및 HV 히터, 산업기기 인버터 등을 타겟으로 하는 자동차 기기 신뢰성 규격 AEC-Q101에 준거하는 1200V 내압으로 저손실 특성과 높은 단락 내량을 실현한 제4세대 IGBT를 개발했다고 8일 발표했다.

이번에 판매하는 제품은 디스크리트 패키지 TO-247-4L 및 TO-247N 2종에 △RGA80TRX2HR △RGA80TRX2EHR 등 총 4개 기종과 베어칩 11개 기종이며, 향후 라인업을 한층 더 확충할 예정인 것으로 전해진다.

.jpg)

▲자동차기기 대응품의 손실 비교 / (자료:로옴)

제4세대 1200V IGBT는 외부 구조를 포함한 디바이스 구조를 개선함으로써 1200V의 고내압과 자동차기기 규격의 신뢰성을 확보했다. 또한 높은 단락 내량 10µsec. (Tj=25℃ 시) 및 낮은 스위칭 손실 특성, 낮은 도통 손실 특성을 달성했다.

또한, 4단자를 채용한 TO-247-4L 패키지 제품은 단자간 연면 거리를 확보해 오염도 2의 환경에서 실효 전압 1100V에 대응할 수 있어, 기존품 대비 고전압 용도에 대응 가능한 것이 특징이다. 연면 거리 대책을 디바이스 측에서 실시함으로써, 메이커의 설계 부하 경감에도 기여할 수 있다.

TO-247-4L 패키지 제품의 경우, 켈빈 에미터 단자를 추가함으로써 고속 스위칭도 실현했으며, 높은 저손실화도 달성했다고 강조했다. 실제로 신제품의 TO-247-4L 패키지 제품과 일반품 및 기존품의 효율을 3상 인버터 조건에서 비교한 결과, 일반품 대비 약 24%, 기존품 대비 약 35%의 손실 저감을 실현해 어플리케이션의 고효율 구동에 기여했다고 밝혔다.

신제품은 월 100만개의 생산 체제로 양산을 개시했다. 생산 거점은 전공정 로옴 주식회사, 후공정 ROHM Integrated Systems(Thailand) Co., Ltd. (태국)인 것으로 전해졌다.

.jpg)