[편집자주] 2025 스마트공장·자동화산업전에서 ST마이크로일렉트로닉스는 IO-Link 기술을 접목한 다양한 스마트 공장자동화 솔루션을 선보이며 참관객들의 이목을 집중시켰다. 진동 센서, ToF 센서, RFID 리더기 등 IO-Link 기반의 제품들은 선보였으며, 한국 시장에서 점차 IO-Link에 관심이 점점 늘어나고 있다는 후문도 전해들을 수 있었다.

ST, AW 2025서 IO-Link 기반 제품 소개

턴키 솔루션 통해 고객의 빠른 제품화 지원

[편집자주] 2025 스마트공장·자동화산업전에서 ST마이크로일렉트로닉스는 IO-Link 기술을 접목한 다양한 스마트 공장자동화 솔루션을 선보이며 참관객들의 이목을 집중시켰다. 진동 센서, ToF 센서, RFID 리더기 등 IO-Link 기반의 제품들은 선보였으며, 한국 시장에서 점차 IO-Link에 관심이 점점 늘어나고 있다는 후문도 전해들을 수 있었다.

ST마이크로일렉트로닉스 강양구 대리를 만나 스마트팩토리에 적용되는 ST의 IO-Link 기반의 다양한 제품과 솔루션들을 함께 살펴봤다.

▲ST마이크로일렉트로닉스 강양구 대리가 IO-Link 기반 스마트팩토리 솔루션을 소개하고 있다.

▲ST마이크로일렉트로닉스 강양구 대리가 IO-Link 기반 스마트팩토리 솔루션을 소개하고 있다.

이번 전시회에 참여하게 된 계기는 ST 제품을 소개해드리기 위해 참여하게 됐다. 여기에서 보이는 제품들은 주로 IO-Link를 접목한 제품들이 많이 있다.

IO-Link를 접목한 △진동(Vibration) 센서 △ToF 센서 △RFID 리더기 △입력(Input)보드 △마스터 보드 △타워 라이트(Tower Light) △솔레노이드 밸브 드라이버 △디지털 출력(Output)보드 △PLC 보드 등이 있다.

▲ST마이크로일렉트로닉스 스마트 공장자동화 시스템 데모

■ 스마트 공장자동화 시스템 관련 시장 추세는?

지금 스마트팩토리 필드에서 요구하는 것은 IO-Link를 접목해서 제품들을 연결하는 추세에 있다. 고객들은 주로 하드웨어와 소프트웨어를 통합해 모든 것이 구축돼 있는 솔루션을 원한다.

■ ST의 공장자동화 시스템 제품들이 주목받는 이유는?

해당 제품이 주목받는 이유는 현재 ST에서 여러가지 솔루션을 제공하고 있다는 것이 주목할 점이다. 그래서 고객들에게 제품을 빨리 적용할 수 있다.

최종적으로 PLC가 있으며 여기에 들어가는 ST 솔루션으로 ST MCU가 있으며, 센서들이나 그밖의 IO-Link 통신을 하기 위한 L6360이나 L6364가 있다.

■ 주요 적용처는?

현 데모들은 공장 자동화에 쓸 수 있는 제품들이다. IO-Link를 접목한 시스템에 적용할 수 있다.

한 예로 버튼을 눌렀을 때, 인풋보드가 신호를 받으며, 그 다음에 받은 신호를 IO-Link 마스터가 정보를 받아서 최종적으로 PLC로 가게 된다. 이러한 PLC가 정의된 로직에 따라서 프로그램이 실행되고, 그거에 따라서 타워 라이트가 켜지게 된다.

그래서 이러한 시스템을 구축하는 업체 혹은 각각의 제품들을 가지고 제품화시키는 고객들에게 많은 도움이 될 것으로 생각된다.

■ 주요 이점 및 경쟁사 대비 차별점은?

주요 이점의 경우 ST는 반도체만 제공하는 게 아니라 턴키 솔루션을 통해 완제품 형태로 고객이 빨리 적용할 수 있게 제품화를 할 수 있다.

경쟁사 제품 대비 차별점의 경우, 보통 경쟁사들은 칩만 판매한다면 ST는 토탈 솔루션을 통해 빠르게 그리고 가격을 저렴하게 제공할 수 있다.

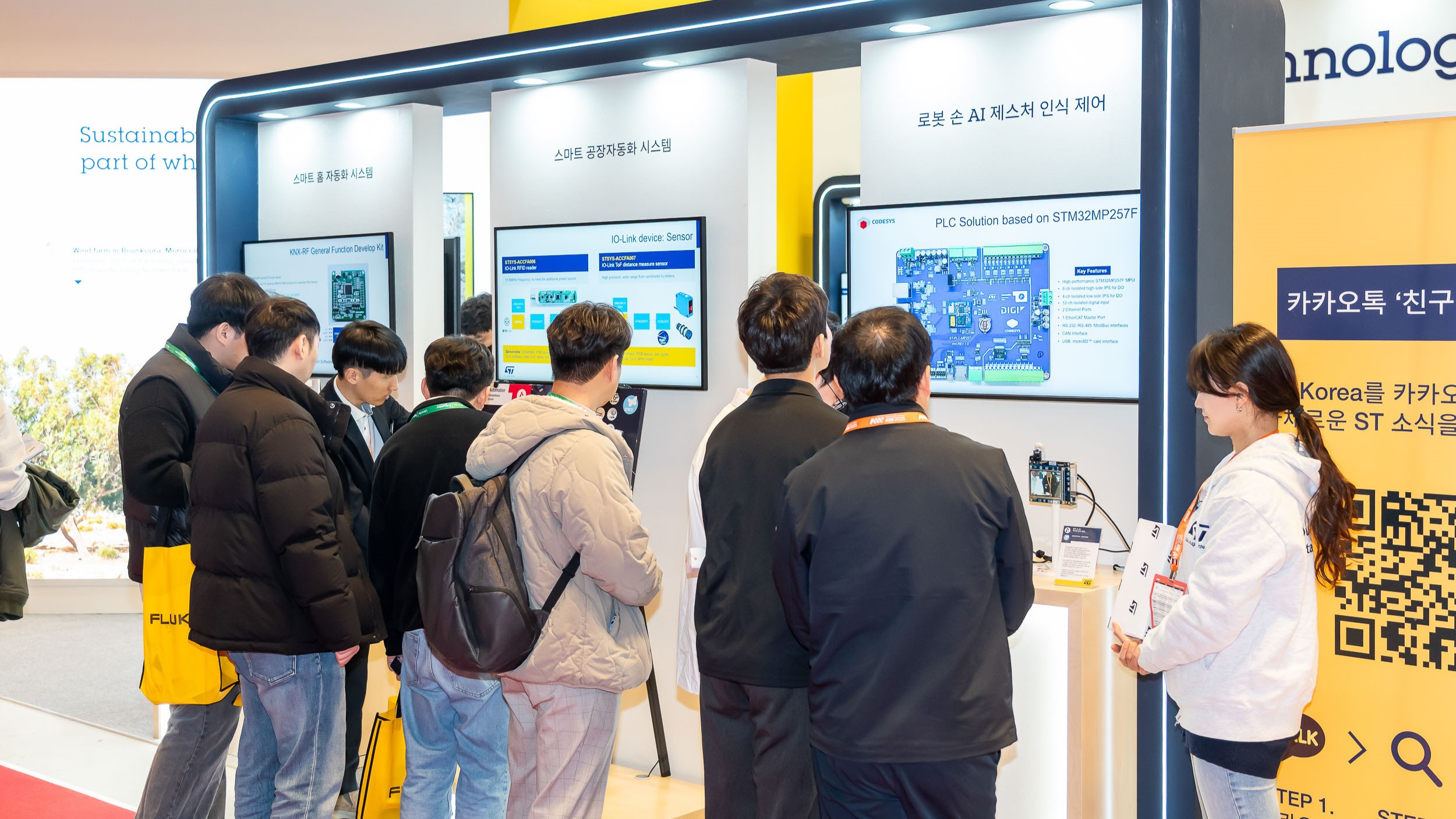

▲ST마이크로일렉트로닉스 부스를 관람하는 참관객 모습

■ 이번 전시회에서 현장 반응들은 어떠했는지

계속 진행하면서 학생들이나 기업체 분들을 계속 만나게 된다. 기존의 중국이나 유럽쪽 경우는 IO-Link 통신이 접목돼 있는데, 한국은 약간 부족한 점이 있었다.

이전부터 계속 해오면서 IO-Link에 관심이 점점 늘어나고 있다라는 걸 느끼게 된다.

(2부에서 계속)