한국전기연구원(KERI) 전기소재공정연구센터 최정희 박사팀이 한양대 이종원 교수팀, 경희대 박민식 교수팀과 함께 급속충전 조건에서도 리튬이온전지의 충·방전 안정성 확보 및 장수명(long-life)을 실현할 수 있는 핵심기술을 개발했다.

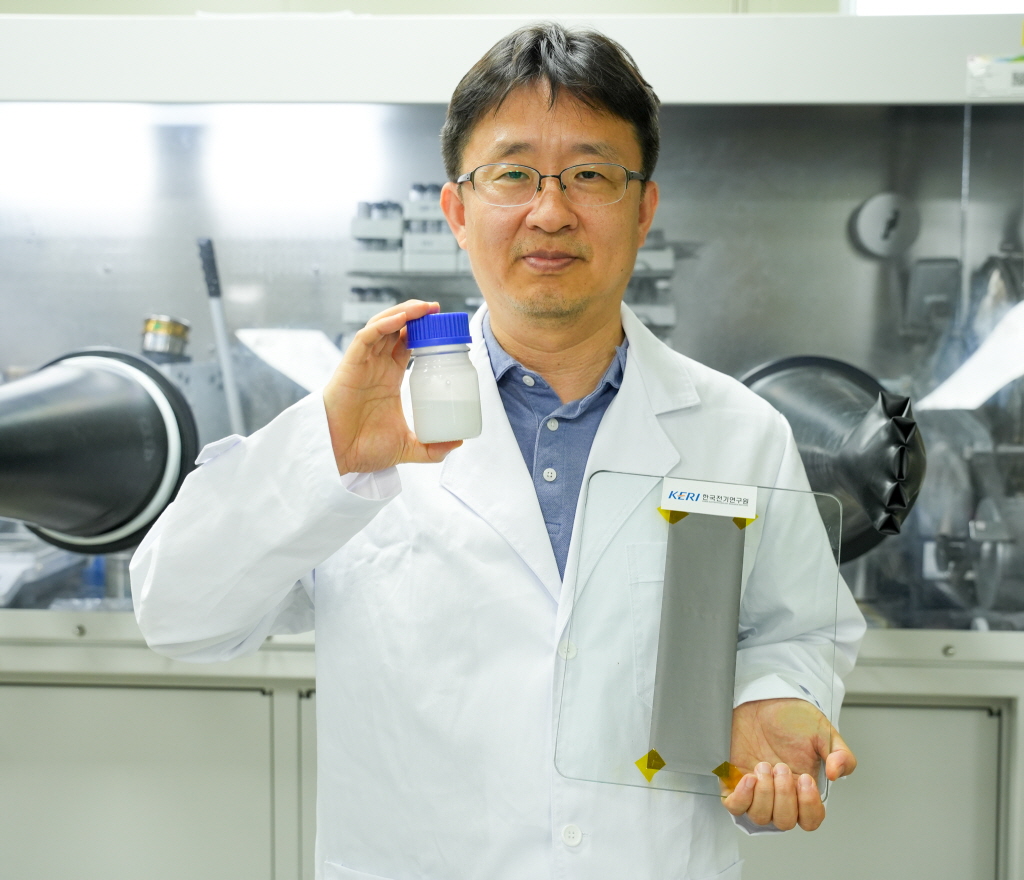

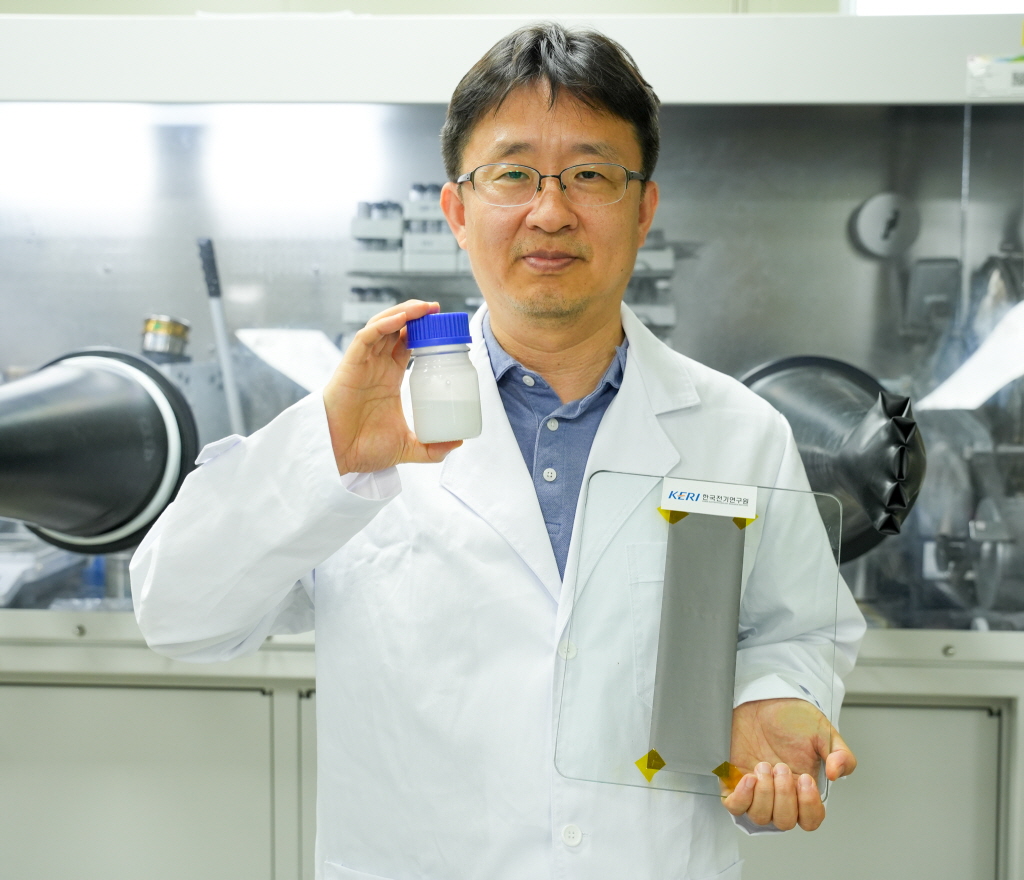

▲KERI 최정희 박사가 산화알루미늄 분산액(왼쪽)과 이를 적용한 리튬이온전지 음극(-) 전극을 들고 있다.

전기연, 산화알루미늄 코팅 기반 ‘음극 표면처리 기술’

표면 처리하는 단순 공정, 가역적 리튬의 양 감소 억제

전기차 급속충전에도 안정적인 고에너지밀도 리튬이온전지를 구현 할 수 있는 기술이 개발돼 전기차 보급 확대에 기여할 것으로 기대된다.

한국전기연구원(KERI) 전기소재공정연구센터 최정희 박사팀이 한양대 이종원 교수팀, 경희대 박민식 교수팀과 함께 급속충전 조건에서도 리튬이온전지의 충·방전 안정성 확보 및 장수명(long-life)을 실현할 수 있는 핵심기술을 개발했다.

전기차 보급 확대를 위한 가장 핵심적인 해결 과제에는 주행거리 상승과 안전성 확보 등 기술적 이슈가 있으며, 사용자 편의를 위한 빠른 충전 속도 역시 요구된다.

반면에 고에너지밀도의 리튬이온전지를 설계하기 위해서는 전극의 두께가 높아야 하는데, 이럴 경우 지속적인 급속충전 시 열화(劣化) 발생 등 전지의 성능이 떨어지는 문제가 발생했다.

이에 KERI가 찾아낸 방법은 리튬이온전지 음극(-) 극판 표면에 1마이크로미터(㎛) 이하의 아주 작은 ‘산화알루미늄(Al2O3)’ 입자를 부분 코팅하는 것이었다.

그동안 국내외 많은 연구진이 음극 소재(흑연 등)에 기능성 나노기술을 도입하는 등 주로 전극 내부 활물질 소재에 집중했다면, 최정희 박사팀은 전극 표면에 산화알루미늄을 코팅하는 단순한 처리 기술로 문제를 해결했다.

산화알루미늄은 가격이 저렴하고, 우수한 전기 절연성, 내열성, 화학적 안정성, 기계적 특성을 보유하고 있어 각종 세라믹 분야에서 널리 사용되고 있는 물질이다.

KERI 연구진은 산화알루미늄 입자가 리튬이온전지 음극과 전해질 간의 계면을 효과적으로 제어하고, 리튬 이온의 빠른 이동을 유도한다는 것을 확인했다.

이를 통해 급속충전 시에도 리튬의 전착(충·방전이 불가능한 비가역적 리튬)을 막고, 리튬이온전지의 안정적인 충·방전 수명을 확보할 수 있었다.

기술의 또 다른 장점은 리튬이온전지의 고에너지밀도화를 추진할 수 있다는 것이다.

리튬이온전지의 성능과 안정성을 높이기 위해 전극 내부 소재에 다른 기능성 소재를 도입하면 합성 공정도 복잡하고, 정작 가역적인 리튬의 양(초기효율)이 떨어지는 단점이 발생한다.

또한 전극의 두께도 두꺼워지며, 급속충전 조건에서 성능이 떨어질 수밖에 없다.

반면에 KERI 기술은 내부가 아닌 흑연 음극 표면을 처리하기 때문에 가역적인 리튬의 양 감소 없이, 고에너지밀도의 후막 전극에 대해 급속충전을 적용하여도 안정적인 성능 구현이 가능하다.

연구팀은 다양한 검증을 통해 산화알루미늄이 코팅된 고에너지밀도의 음극 전극(4.4 mAh/cm2)이 500회의 급속충전에도 83.4% 이상 성능(잔류 용량비)을 유지하는 등 세계최고 수준의 우수성을 가지는 것을 확인했다.

현재 500mAh급 파우치 셀까지 효과 검증을 진행했고, 향후 스케일 업(scale-up)을 통해 대면적 중대형 용량의 전지에서도 적용될 수 있도록 기술을 발전시킨다는 계획이다.

최정희 박사는 “편리한 급속충전과 리튬이온전지의 에너지밀도는 상충 관계(trade-off)처럼 여겨져 전기차의 대중화를 막는 원인 중 하나”라며 “우리의 성과를 통해 급속충전에도 안정적인 고에너지밀도 리튬이온전지를 구현할 수 있을 것으로 기대하고, 전기차 보급 확대와 범국가적 탄소중립 실현에 크게 기여할 수 있을 것”이라고 전했다.

이번 연구결과는 우수성을 인정받아 국내는 물론, 미국 특허 등록도 마쳤으며, 재료공학 분야 국제 저명 학술지인 ‘Advanced Functional Materials’에도 최근 논문이 게재(JCR Impact Factor 19, 상위 3.7%)됐다.

한편 KERI는 과학기술정보통신부 국가과학기술연구회 산하 정부출연연구기관이다. 이번 연구는 삼성미래기술육성사업 및 산업부 산업기술혁신사업(전기차 고출력 배터리 및 충전시스템 기술 개발)으로 진행됐다.