한국재료연구원 에너지·환경재료연구본부 김재호, 송명관 박사 연구팀이 부산대 오진우 교수 및 공주대 최진우 교수와 공동 연구를 통해, 하이브리드 바이오 나노구조체를 개발하고, 이를 이용해 영하 80℃ 및 상온 150℃까지 고성능과 안정성을 가진 섬유형 태양전지와 섬유형 유기 발광 다이오드를 제작하는 데 성공했다.

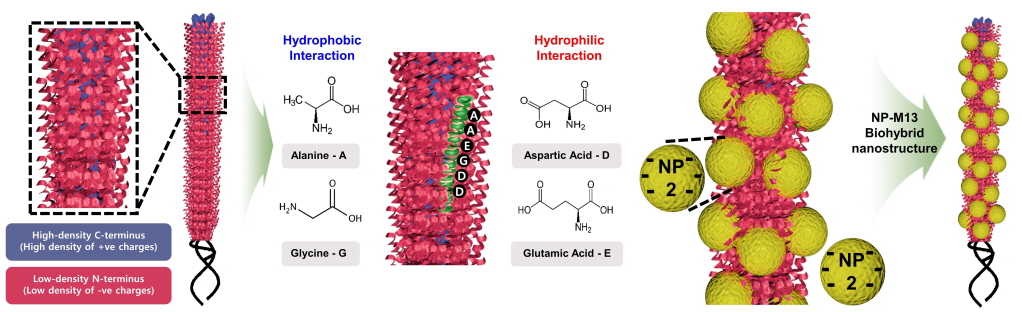

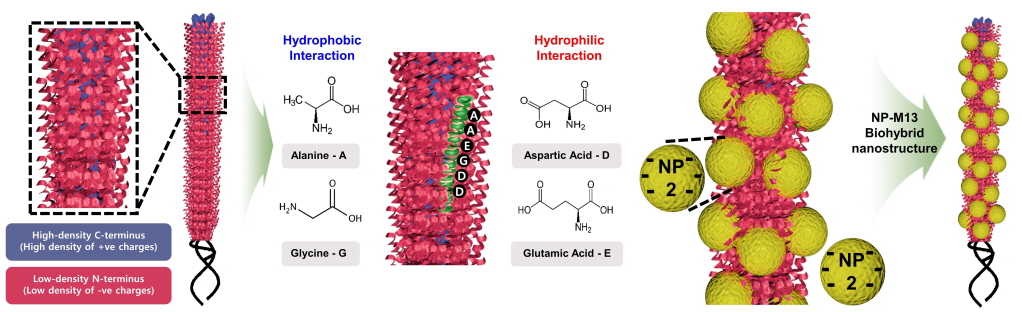

▲하이브리드 바이오 나노구조체 합성과정

부산대·공주대와 함께 고성능 하이브리드 바이오 나노구조제 개발

한국재료연구원(KIMS, 원장 최철진)이 하이브리드 바이오 나노구조체 개발에 나서, 향후 이를 이용한 태양전지, 유기발광다이오드, 센서 등 산업 전반에 필요한 전자소자 제작이 본격화 할 것으로 기대가 모아진다.

재료연 에너지·환경재료연구본부 김재호, 송명관 박사 연구팀이 부산대 오진우 교수 및 공주대 최진우 교수와 공동 연구를 통해, 하이브리드 바이오 나노구조체를 개발하고, 이를 이용해 영하 80℃ 및 상온 150℃까지 고성능과 안정성을 가진 섬유형 태양전지와 섬유형 유기 발광 다이오드를 제작하는 데 성공했다고 10일 밝혔다.

연구팀은 해당 섬유형 태양전지의 광전효율은 40%, 섬유형 유기 발광 다이오드의 발광효율은 48% 증가했음을 확인했다.

기존 금속나노입자의 보편적인 코팅 방법 중 하나인 ‘스핀코팅’ 방법은 누구나 빠르고 간단하게 박막을 만들 수 있는 장점이 있지만, 금속나노입자를 균일하고 질서정연하게 코팅할 수 없다는 단점이 있었다.

이를 개선하고자 연구팀은 금속나노입자를 균일하고 질서정연하게 배치하는 특성을 가진 바이오 물질 ‘M13 박테리오파지’를 합성했다.

M13 박테리오파지는 금속 양이온과 결합하는 활성기를 가져, 모든 금속 양이온을 일정하게 배열한다.

따라서 M13 박테리오파지를 합성한 하이브리드 바이오 나노구조체는 공기와 수분에 높은 안정성을 가져, 이를 이용해 고성능의 섬유형 태양전지와 섬유형 유기발광 다이오드를 제작할 수 있다.

또한 극한 환경(영하 80℃ 및 상온 150℃) 및 세탁 특성도 매우 우수한 특성을 나타냈음을 확인했다.

M13 박테리오파지는 압전소자 및 태양전지, 센서, 유기발광 다이오드 등 다양한 전자소자 분야에서 활용이 가능하다.

하이브리드 바이오 나노구조체를 이용한다면, 금속 나노입자의 배열구조와 정렬을 쉽게 설정할 수 있다는 게 기술의 차별성이다.

또한 표면 플라즈모닉 효과를 극대화할 수 있어, 다양한 전자소자에 응용이 가능하다.

본 기술을 활용해 국산화 및 대량화를 앞당길 경우, 전자소자 기업에서의 파격적인 경제적 효과를 기대할 수 있을 것으로 전망된다.

연구책임자인 재료연 송명관 책임연구원은 “하이브리드 바이오 나노구조체를 활용하면, 전자소자 분야에서 성능향상과 안정성을 함께 증가시킬 수 있다”라며 “향후 에너지 생산 및 저장 소재뿐만 아니라, 센서 소재 등 다양한 분야에 적용이 기대된다”고 말했다.

본 연구성과는 과학기술정보통신부의 지원으로, 한국재료연구원 기본사업(섬유타입의 에너지 생산 및 저장 플랫폼 개발), 한국연구재단 중견연구자지원사업을 통해 수행됐다. 또한 연구결과는 스몰 스트럭쳐즈(Small Structures)에 5월7일 자로 게재됐다. 현재, 연구팀은 다양한 바이오 나노구조체를 개발해 유기 전자소자 및 체외진단용 센서 등에 활용할 수 있는 후속 연구를 지속해서 진행하고 있다.